- Home

- About Us

- Products

WATER TREATMENT

-

Bio floc TM

-

Bio ifas TM

-

Eco floc TM

-

Eco Chem TM

AIR TREATMENT

-

Wet pack TM

-

Wet turi TM

-

Dust bag TM

-

Dust clo TM

STEAM BOILERS

-

Pack Max TM

-

Pax Max TM

-

Fire Max TM

-

Fire Max TM

-

- Buisness with us

- Career with us

- Knowledge Base

- Contact Us

DENR DAO 2016-08 & DAO 2021-19 COMPLIANCE

Our MBBR (Moving Bed Biofilm Reactor) wastewater treatment system stands as a testament to our commitment to cutting-edge technology and environmental sustainability. It has been meticulously designed to ensure compliance with the regulatory standards set forth by the Philippines DENR (Department of Environment and Natural Resources) and hence meticulously engineered to align with the Effluent Water Quality standards outlined in DENR DAO 2016-08

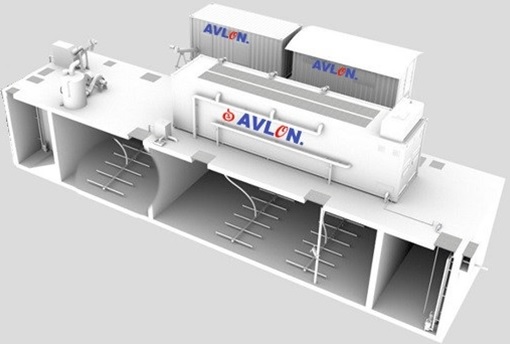

MBBR – LOW INITIAL INVESTMENT TREATMENT PLANT

Our MBBR technology ensures the lowest Capital Expenditure by optimizing the use of cost-effective materials and resources. Moreover, its inherent efficiency in biological wastewater treatment guarantees low Operating Expenditure through reduced energy consumption, minimal maintenance requirements, and extended service life, setting it apart as the most cost-effective choice compared to traditional treatment technologies

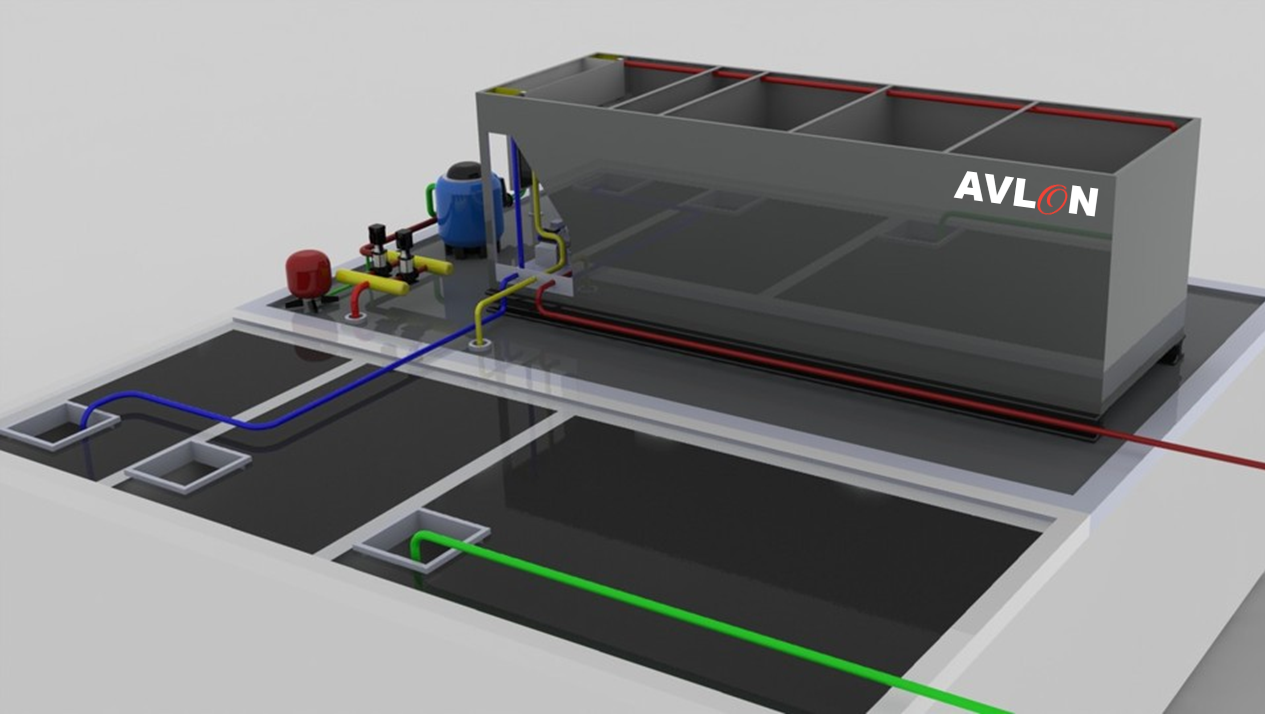

AVLON YOUR ONE STOP SHOP

We offer a comprehensive turnkey solution to address your wastewater challenges, encompassing everything from innovative design engineering and meticulous fabrication to expert civil construction, precise manufacturing, seamless installation, and thorough commissioning. Additionally, we ensure regulatory compliance by securing DENR discharge permits, and our commitment extends beyond project completion, with dedicated after-sales support, technical assistance, and readily available spare parts to guarantee the long-term success of your wastewater treatment system.

OUR OFFERING

OUR MBBR PROCESS FLOW EXPLAINED

INFLUENT WASTEWATER: The first step in the process is to receive the influent wastewater from the municipal sewer system or industrial discharge. This wastewater is often screened to remove large debris and grit.

PRIMARY TREATMENT: The wastewater then undergoes primary treatment, which involves the removal of settleable and floating solids, as well as some organic matter. This is typically done in a settling tank or clarifier.

Within the secondary stage, the MBBR system comprises three distinct tanks:

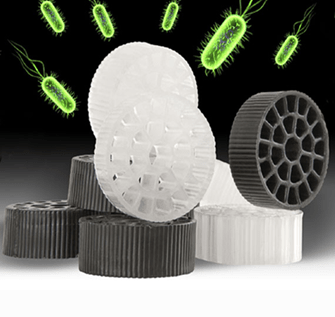

MBBR REACTOR TANK FOR BOD REMOVAL: This tank is meticulously designed to effectively eliminate BOD (biological oxygen demand) from wastewater. It serves a crucial role in BOD removal by providing ample surface area for microorganisms to consume organic matter. This reactor typically contains more plastic media than the second MBBR reactor, optimizing surface area for biofilm formation. The biofilm functions as a natural filter, efficiently removing organic matter and other contaminants from the wastewater.

MBBR REACTOR TANK FOR BIO NUTRIENT REMOVAL (BNR): The second MBBR reactor, often positioned in series with the first, is primarily focused on removing bio-nutrients like ammonia, nitrate, nitrite, and phosphate from the wastewater stream. BNR is accomplished through a two-stage process: ammonia oxidation and nitrite oxidation. Avlon's design ensures specific factors, including Oxic SRT, MLSS, alkalinity, influent ammonia levels, and the presence of inhibitory compounds, are maintained for effective nitrification.

PRE/POST ANOXIC TANK FOR DENITRIFICATION: This tank is skillfully designed to facilitate denitrification, converting nitrate (NO3-) produced in the second MBBR reactor into nitrogen gas (N2), released harmlessly into the atmosphere. Denitrification occurs in low-oxygen conditions, and the process involves the introduction of a carbon source to stimulate denitrifying bacterial growth. Denitrifying bacteria, such as Paracoccus denitrificans, Pseudomonas denitrificans, and Thiobacillus denitrificans, utilize the carbon source as an electron donor, and nitrate as an electron acceptor, effectively converting nitrate to nitrogen gas.

FINAL CLARIFIER: The treated wastewater then undergoes final clarification to remove any remaining suspended solids or bacteria. This is typically done in a settling tank or clarifier.

DISINFECTION: Finally, the treated wastewater is disinfected to kill any remaining bacteria and viruses. This is typically done using chlorine, UV light, or ozone.

EFFLUENT DISCHARGE: The treated and disinfected wastewater, known as effluent, is then discharged into a receiving water body or reused for non-potable purposes, such as irrigation or industrial use.

ADVANTAGES OF AVLON MODULAR MBBR PLANT

Avlon modular MBBR wastewater treatment plant offers several advantages that can make it an attractive choice for various applications.

QUICK INSTALLATION: Our Modular systems are pre-fabricated and assembled off-site, reducing on-site construction time and disruptions. This results in faster installation and commissioning, minimizing downtime and project delays.

SPACE EFFICIENCY: Our Modular MBBR plants are designed to maximize the use of available space. They have a compact footprint, making them suitable for locations with limited space, such as urban areas or industrial facilities with space constraints.

EASE OF EXPANSION: If future expansion is required, adding modules to a our modular MBBR system is straightforward. This scalability allows for long-term planning and cost-effective upgrades as wastewater treatment needs evolve.

QUALITY CONTROL: Modular systems are often manufactured in controlled environments, ensuring consistent quality and performance across all modules. This helps maintain treatment efficiency and reliability.

RELIABILITY: Our Modular MBBR systems are designed for ease of operation and maintenance. They often incorporate advanced control systems and monitoring, making it easier to ensure optimal performance and troubleshoot issues when they arise.

COST-EFFECTIVE: By reducing construction and installation time, modular MBBR systems result in cost savings compared to custom-built treatment plants. Additionally, their scalability means that investments can be phased as needed, aligning with budget constraints.

In summary, our modular MBBR wastewater treatment plants offer flexibility, efficiency, and scalability, making them a versatile and cost-effective choice for a wide range of wastewater treatment applications. Their quick installation, space-saving design, and adaptability to changing needs make them an attractive option for many organizations.

-

Available in Module or Civil structure.

-

Compact units with less foot print

-

Complete solids removal

-

Improved settling characteristics

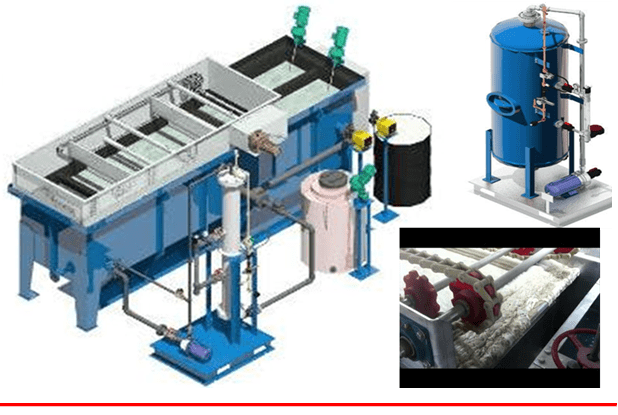

DISSOLVED AIR FLOTATION

The AVLON Dissolved Air Flotation (DAF) systems use chemical pre treatment and micro air bubbles to separate contaminants from water. Our DAF is the perfect combination of DAF System and Sedimentation process and implements solid-liquid separation most efficiently. When this water is released into the skimming tank under atmospheric conditions, micro-bubbles form and carry the suspended solids to the surface for removal.

AVLON DAF allows plant operations to process 6 to 10 times less sludge by thickening first, meaning sludge treatment and disposal are decreased dramatically, resulting in a significant savings for customers.

-

Enhanced process stability

-

No need of periodic backwashing

-

Low capital costs

-

Low running costs

Ammonification, Nitrification & Denitrification for Nitrogen Removal

Nitrogen exists in several forms. The principal nitrogen types of concern to wastewater treatment are: Total Nitrogen, Total Kejeldahl Nitrogen (TKN), Ammonia, Organic Nitrogen, Nitrate and Nitrite. Total Nitrogen (TN) is the sum of nitrate-nitrogen (NO3-N), nitrite-nitrogen (NO2-N), ammonia-nitrogen (NH3-N) and organically bonded nitrogen. Total Nitrogen (TN) should not be confused with TKN (Total Kjeldahl Nitrogen) which is the sum of ammonia-nitrogen plus organically bound nitrogen but does not include nitrate-nitrogen or nitrite-nitrogen.

In biofloc most of the organic nitrogen (N2) is changed to ammonia (NH3) in a process known as ammonification starting from the service connection then we our system automatically control Ph for the transformation to ammonia and ammonium. Biological nitrogen removal is a two-step process that involves nitrification and denitrification. Nitrification is an oxidizing process that occurs in the presence of oxygen under aerobic conditions using bacteria (often Nitrosomonas) to oxidize ammonia to nitrite, and then using another type of bacteria (often Nitrobacter) to oxidize the nitrite (NO₂) to nitrate (NO₃). Denitrification is a reducing process that occurs in the absence of oxygen under anoxic conditions using heterotrophic bacteria (usually Pseudomonas) to reduce nitrate to nitric oxide, nitrous oxide and nitrogen gas.

-

Easy operation and maintenance

-

High nitrogen & phosphorus removal

-

Easy to install

-

Long-lasting desludging period.