- Home

- About Us

- Products

WATER TREATMENT

-

Bio floc TM

-

Bio ifas TM

-

Eco floc TM

-

Eco Chem TM

AIR TREATMENT

-

Wet pack TM

-

Wet turi TM

-

Dust bag TM

-

Dust clo TM

STEAM BOILERS

-

Pack Max TM

-

Pax Max TM

-

Fire Max TM

-

Fire Max TM

-

- Buisness with us

- Career with us

- Knowledge Base

- Contact Us

REVERSE OSMOSIS (RO)

Reverse Osmosis stands as a high-pressure, energy-efficient marvel in the world of water treatment. It excels in the dehydration of process streams, concentrating low molecular weight compounds, and purifying waste effluents. Its versatile applications encompass pre-concentration in dairy and food processing, the refinement of evaporator condensate, and the meticulous purification of crucial process water.

NANOFILTRATION (NF)

Nanofiltration, occupying a unique niche between Ultrafiltration (UF) and RO, is tailored for the precise separation of low molecular weight compounds—think minerals and salts—from intricate process streams. Its remarkable utility extends to deashing dairy products, recovering hydrolyzed proteins, concentrating sugars, and purifying soluble dyes and pigments, ensuring precision in complex separations.

ULTRAFILTRATION (UF) & MICROFILTRATION (MF)

Ultrafiltration is a discriminating filtration technique celebrated for its prowess in concentrating and refining medium to high molecular weight components. Whether it's the concentration of whey proteins, the deashing and concentration of gelatin, or the clarification of fruit juices, UF is the trusted choice in applications where selective separation is paramount.

Microfiltration, offering gentle yet effective separation, is adept at isolating sizable molecular weight suspended or colloidal compounds from dissolved solids. It plays a vital role in diverse areas, from harvesting cells in fermentation broths and fractionating milk proteins to clarifying corn syrup and facilitating CIP (Clean-in-Place) chemical recovery. Its versatility knows no bounds in achieving precision and efficiency.

OUR OFFERING

Streamlined Operational Framework

Our reverse osmosis (RO) system operates seamlessly to ensure the highest water quality standards. Here's an overview of the process:

Inlet Filtration: Raw water initiates its journey through sediment pre-filters, effectively removing particles and preparing it for further treatment.

Chemical Enhancement: At this stage, the water is precisely dosed with antiscalant and other RO chemicals, a crucial step facilitated by a dosing pump. This treatment step primes the water for the rigorous separation process ahead.

High-Pressure Pumping: The high-pressure pump directs the treated water into the heart of the system—the membrane module or membrane array. It is here that the magic of separation occurs, dividing the incoming feed stream into purified and concentrated streams.

Concentration Management: A portion of the concentrated stream is discharged safely, while the remainder is strategically routed back to the suction end of the high-pressure pump, aptly known as concentrate recycle.

Controlled Discharge: To regulate the rate of concentrate discharge and define the proportion of purified water (permeate) to wastewater (concentrate), a drain flow control mechanism is meticulously integrated. The equilibrium achieved is termed "recovery."

Recycle Optimization: The recycle line is equipped with a flow control system that governs the recycle flow rate, maintaining the essential working pressure within the membrane array. The rate of permeate production is intricately linked to the pressure within the membrane modules.

Permeate Harvesting: The purified permeate flows through the permeate outlet and into the permeate tank, ensuring the pristine quality of the treated water.

Smart Monitoring: Our system operates under the watchful eye of a sophisticated process controller. This controller orchestrates the actions of pumps and valves, executing timely service routines and membrane rinsing protocols as needed. It draws insights from pressure switches, float switches, permeate conductivity and temperature sensors, and external input. Based on these signals, it seamlessly transitions between service mode, membrane rinse cycles, standby, or fault mode.

This comprehensive operational framework guarantees that our RO system consistently delivers the highest quality water, with automated safeguards in place to ensure performance and reliability.

HIGH QUALITY PUMPING SOLUTIONS

The sustainability of water treatment solutions requires that the pumping solution is durable, ensuring cost effective and trouble-free operation. In AVLON product we are only using Grundfos pumps which has external frequency converters (CUE) for variable speed drives and motor protection (MP204) to monitor motor conditions ensure optimal adaptation to changing conditions. This ensures a perfect match with hydraulics, motors, electrics, and all other mechanical components that make up a comprehensive pumping solution.

AVLON incorporates in its system DENMARK Manufactured pumping system which are built on more than 45 years of process engineering experience - providing high quality, world class manufacturing to our Philippines customer.

-

Hot water sanitizable elements

-

Custom-made elements for various special applications.

-

Chlorine resistant NF elements

-

Pre-rinsed ultra pure water elements.

MANUFACTURED IN PHILIPPINES - YOUR BENEFIT

PRODUCTS ARE IN HIGH QUALITY AND LOCALLY MADE WITH AFTER SALES SERVICE SUPPORT

Your benefit – Avlon works with reliable and reputable suppliers that are known in the industry and are available in the Philippines. We fabricate and manufacture our product locally and we welcome clients to visit our site in Batangas. In Avlon, we take pride in our extended support to our clients from technical, repair and spare parts inquiries. We are just a call away and our engineers will be there at your service anytime and anywhere in the country.

PRODUCTS ARE IN COMPLIANCE WITH DENR STANDARDS AND LOCAL GOVERNMENT POLICIES

Your benefit – Avlon stands guarantee to our products. We make sure that we meet RA 9275 clean water act & RA 8749 clean air act.

PRODUCTS ARE FULLY AUTOMATIC

Your benefit – No skilled operator required. Less manpower cost and less maintenance cost.

PRODUCTS HAVE ENERGY SAVING DEVICES

Your benefits – Avlon design incorporates energy saving devices in every equipment and this helps clients to reduce their electrical usage, chemical consumption and other utility cost in a daily basis.

CUSTOMIZED DESIGN

Your benefit – As Avlon knows that every requirement is unique and varies on different factor such as, industry, space, budget and others, we customize our solutions based on what our client needs.

ROBUST DESIGN

Your benefit – In Avlon, quality is our utmost priority. Avlon makes sure that your investment is worthy. Every equipment in our product have a standby system providing redundancy in design and hence helping you to have a trouble-free operation and less maintenance

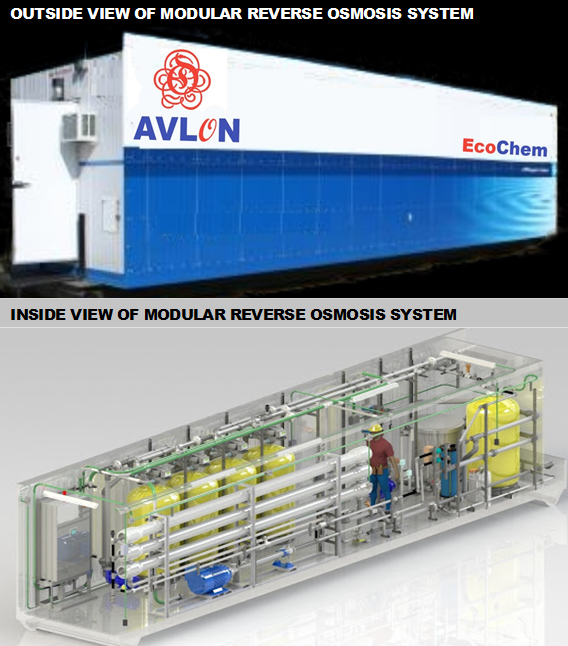

MODULAR DESIGN

Your benefit – Avlon works in every space available and provided by the client. It comes in modules and it requires less time for installation. It can also be transferred from one place to another as it comes in such a way where client has the options to bring it and use it should there be a change in location.

EXPERTISE IN MECHANICAL ENGINEERING AND PROJECT MANAGEMENT

Your benefit - Avlon has a pool of experts in all engineering aspects from local to international certified engineers and have a wide range experience in our product line and project management. Apart from that, our team is composed of highly skilled workers and professionals’ individuals.

NO / MINIMAL CIVIL WORKS

Your benefit – Avlon provides equipment that are modular and plug and play, in which our client can save money in overall cost in NO up to minimal civil works,

ONE STOP SHOP AND END TO END SOLUTION

Your benefit – Avlon is not just a supplier. We are partners. Avlon works hand in hand together with our client from design engineering, fabrication and manufacturing, installation, commissioning, DENR and DOLE permits up to after sales technical support and spare parts supplies.

-

Compact, inline design fits into small footprint.

-

AISI 316 stainless steel throughout

-

Integrated sensor available.

-

Laser welded stainless impellers.