- Home

- About Us

- Products

WATER TREATMENT

-

Bio floc TM

-

Bio ifas TM

-

Eco floc TM

-

Eco Chem TM

AIR TREATMENT

-

Wet pack TM

-

Wet turi TM

-

Dust bag TM

-

Dust clo TM

STEAM BOILERS

-

Pack Max TM

-

Pax Max TM

-

Fire Max TM

-

Fire Max TM

-

- Buisness with us

- Career with us

- Knowledge Base

- Contact Us

CAPACITIES

400 to 10,000 CFM with a single unit & Efficiencies to 99.99%

YOUR BENEFIT

Made in Philippines, Fully Automatic, Energy Saving, Fully Modular, Robust Design, One stop shop & customized solution.

DENR COMPLIANCE

Avlon stands guarantee to our products. We make sure that we meet Philippines DENR RA 8749 Clean Air Act under its latest Regulation DAO 2013-13 on general effluent Standard

OUR OFFERING

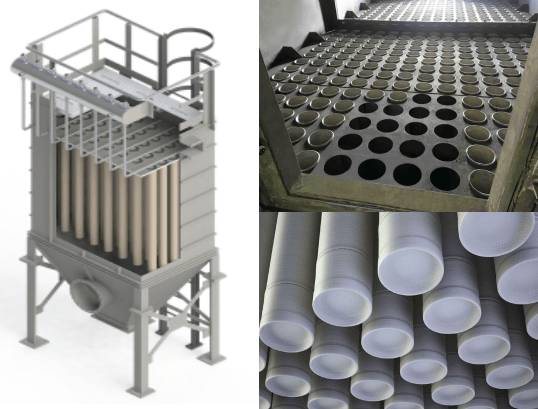

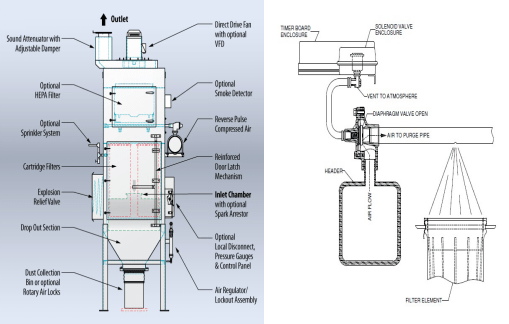

Avlon offers a complete line of dependable, rugged baghouse dust collectors to keep your operation running smoothly. Avlon baghouse dust collectors stand out due to their ability to handle high volumes of dust laden air using a compressed-air self-cleaning system enabling effective reverse blasting through deformation of the filter bags. The unit filters sub-micron sized particles in continuous operating mode and with a steady loss of differential pressure.

Our baghouse dust collector can handle challenging applications such as high temperature, moisture, and heavy dust loading. They are both energy efficient and powerful, and equipped with onboard filter cleaning systems to maximize filter life and reduce maintenance costs. Different media types can handle industrial dust challenges such as wood, paper, chemicals, pharmaceutical, grain, metal, food, powder/bulk, and more, contact our knowledgeable staff for assistance with your application.

Our baghouse has expanded inlet diffusers which prevent hopper turbulence, dust re-entrainment and facilitate material drop-out. It also have expanded quiescent free-board zone between the inlet and the bottom of the filter bags that reduces unnecessary dust load, filter abrasion and interstitial velocity that further enhancing material drop-out all before the air stream even reaches the filters. Finally, it is equipped with “Clean-on-demand” controller systems that allows for bag cleaning based on differential pressure. This results in direct savings from lower compressed air usage, extended filter life, and lower emissions.

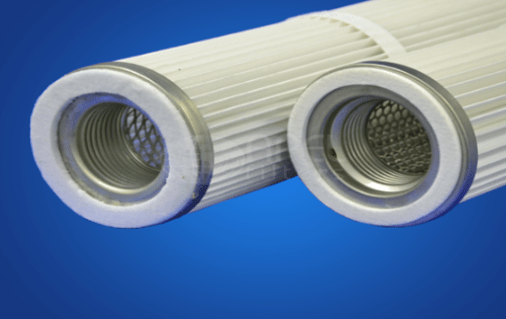

High Quality Cartridge Type Filter Bags

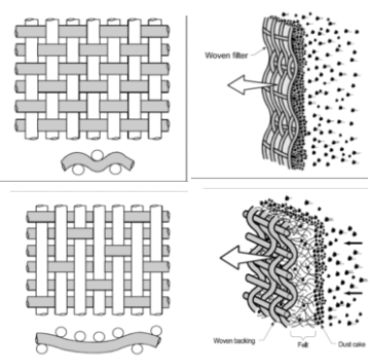

Avlon use more compact and heavier filter medium to lower the air permeability and to reduce pressure drop. Only Non Woven fiber can withstand high pressure cleaning which happens in pulse jet cleaning process. AVLON Pleated bags have built-in cores so they replace both the filter bag and its supporting cage. Some pleated bag designs even have curved openings at their tops to improve cleaning energy.

Low operating costs. Optimized design of process parameters is conducive to efficient and stable operation of the bag filter with low resistance, reducing energy consumption, as well as the loss of the bag. To ensure complete sealing for any type of dust, the filter bags are generally designed to be installed and held firmly in place by either a B-shaped belt, flat belt, cord, double cord or ring. A broad range of treatments and coatings can be applied to either side of the bags to facilitate reverse blasting, increase effectiveness, and extend service life

- Low Air permeability

- High filtration efficiency

- Low pressure drop

- Less operating cost

-

Expanded inlet diffusers.

-

Expanded quiescent free-board zone.

-

Clean-on-demand.

-

Energy Saving Devices.

High Efficiency in Particulate Matter Removal

Ductbag Their ability to filter highly-contaminated air volumes in an extremely compact format is what sets them apart from the rest. True hopper with minimal angles of 60 degrees on the interior slope eliminates the possibility of dust accumulation use more compact and heavier filter medium to lower the air permeability and to reduce pressure drop. Only Non Woven fiber can withstand high pressure cleaning which happens in pulse jet cleaning process.

Best in class efficiency on sub micron particulate. Lower initial & operating pressure drop. Reduction in cleaning cycles, prolongs filter life. Compressed air and energy savings. Reduced outlet emissions. Reduced downtime Pleated bags have built-in cores so they replace both the filter bag and its supporting cage. Some pleated bag designs even have curved openings at their tops to improve cleaning energy.

-

Connection: 1/4″ to 4 ″ BSP.

-

Capacity: 5.5 – 4120 L/min.

-

Spray angles: 60°, 90°, 120°, 150°, 180°.

-

Non-plugging spray nozzles.

MANUFACTURED IN PHILIPPINES - YOUR BENEFIT

PRODUCTS ARE IN HIGH QUALITY AND LOCALLY MADE WITH AFTER SALES SERVICE SUPPORT

Your benefit – Avlon works with reliable and reputable suppliers that are known in the industry and are available in the Philippines. We fabricate and manufacture our product locally and we welcome clients to visit our site in Batangas. In Avlon, we take pride in our extended support to our clients from technical, repair and spare parts inquiries. We are just a call away and our engineers will be there at your service anytime and anywhere in the country.

PRODUCTS ARE IN COMPLIANCE WITH DENR STANDARDS AND LOCAL GOVERNMENT POLICIES

Your benefit – Avlon stands guarantee to our products. We make sure that we meet RA 9275 clean water act & RA 8749 clean air act.

PRODUCTS ARE FULLY AUTOMATIC

Your benefit – No skilled operator required. Less manpower cost and less maintenance cost.

PRODUCTS HAVE ENERGY SAVING DEVICES

Your benefits – Avlon design incorporates energy saving devices in every equipment and this helps clients to reduce their electrical usage, chemical consumption and other utility cost in a daily basis.

CUSTOMIZED DESIGN

Your benefit – As Avlon knows that every requirement is unique and varies on different factor such as, industry, space, budget and others, we customize our solutions based on what our client needs.

ROBUST DESIGN

Your benefit – In Avlon, quality is our utmost priority. Avlon makes sure that your investment is worthy. Every equipment in our product have a standby system providing redundancy in design and hence helping you to have a trouble-free operation and less maintenance

MODULAR DESIGN

Your benefit – Avlon works in every space available and provided by the client. It comes in modules and it requires less time for installation. It can also be transferred from one place to another as it comes in such a way where client has the options to bring it and use it should there be a change in location.

EXPERTISE IN MECHANICAL ENGINEERING AND PROJECT MANAGEMENT

Your benefit – Avlon has a pool of experts in all engineering aspects from local to international certified engineers and have a wide range experience in our product line and project management. Apart from that, our team is composed of highly skilled workers and professionals’ individuals.

NO / MINIMAL CIVIL WORKS

Your benefit – Avlon provides equipment that are modular and plug and play, in which our client can save money in overall CAPEX cost in NO up to minimal civil works,

ONE STOP SHOP AND END TO END SOLUTION

Your benefit – Avlon is not just a supplier. We are partners. Avlon works hand in hand together with our client from design engineering, fabrication and manufacturing, installation, commissioning, DENR and DOLE permits up to after sales technical support and spare parts supplies.

-

Low Air Permeability of Filtering media.

-

Chemical resistance of filtering media.

-

Abrasion factor of filtering media.

-

Larger Filtering surface area.