- Home

- About Us

- Products

WATER TREATMENT

-

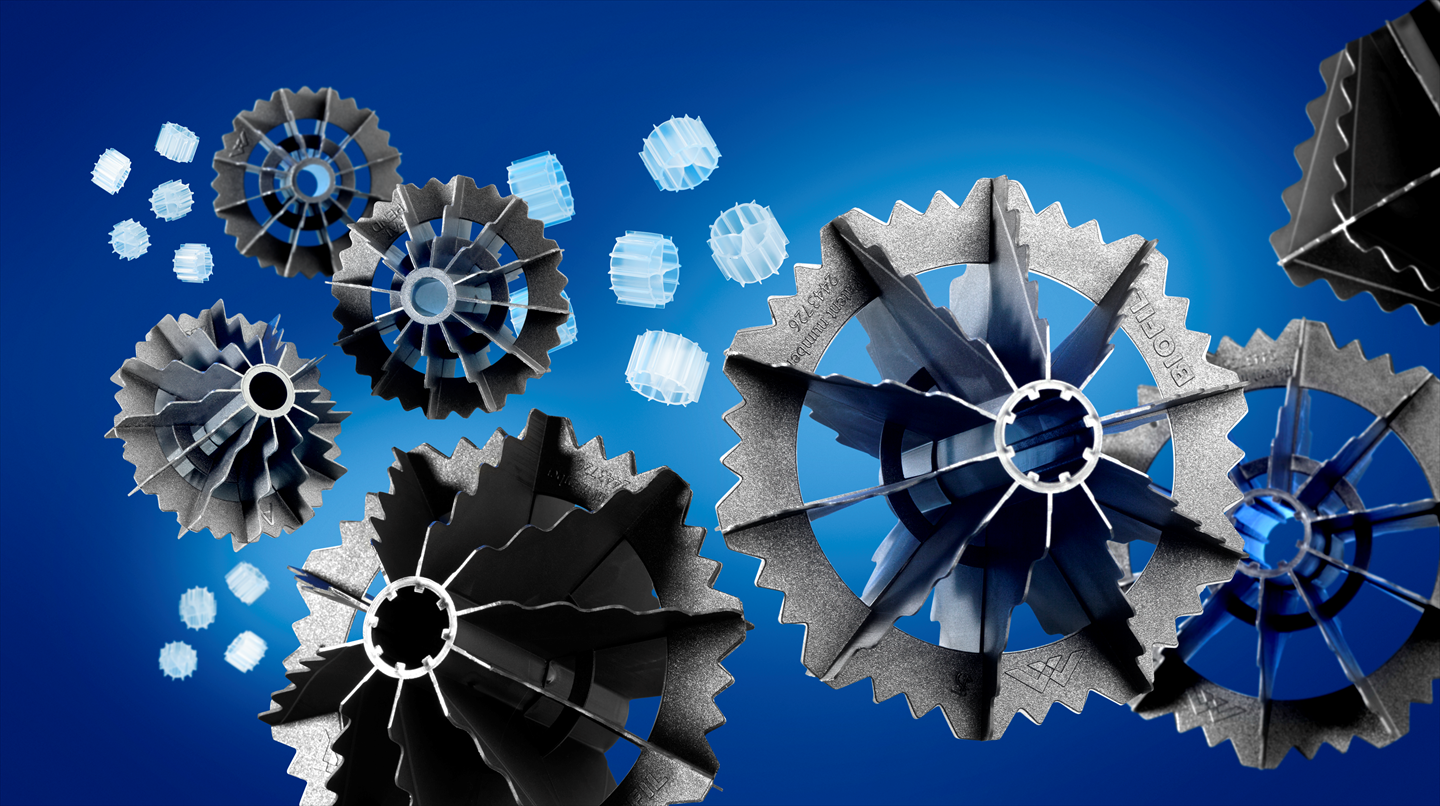

Bio floc TM

-

Bio ifas TM

-

Eco floc TM

-

Eco Chem TM

AIR TREATMENT

-

Wet pack TM

-

Wet turi TM

-

Dust bag TM

-

Dust clo TM

STEAM BOILERS

-

Pack Max TM

-

Pax Max TM

-

Fire Max TM

-

Fire Max TM

-

- Buisness with us

- Career with us

- Knowledge Base

- Contact Us

DENR DAO 2016-08 & DAO 2021-19 COMPLIANCE

Our IFAS (Fixed Film Activated Sludge) wastewater treatment system stands as a testament to our commitment to our customer who want to upgrade their existing sewage treatment plant or wastewater treatment plant without making significant footprint changes or without substantial investment. The IFAS process is a combination of the fixed-film and the suspended activated sludge processes. In general, the addition of media to the aeration basins makes it possible for nitrifying sludge ages to be attained in considerably smaller basin volumes than required for a comparable single-stage activated sludge nitrification process. This system has been meticulously engineered to align with the Effluent Water Quality standards outlined in DENR DAO 2016-08

WHY CONSIDER AN UPGRADE?

There are compelling reasons to consider the upgrade of your current wastewater or sewage treatment facility. Upgrading not only ensures that your plant remains compliant with evolving environmental regulations but also enhances its overall efficiency and performance. By investing in modernization, you can improve treatment quality, reduce operational costs, and extend the lifespan of your infrastructure. Additionally, upgrades enable your facility to adapt to changing treatment needs and emerging technologies, ultimately safeguarding your commitment to sustainable and responsible wastewater management. Reasons for upgrade are:

- DENR has revised the effluent standards

- Need upgrade because of aging equipment

- Need upgrade due to rising cost of energy

- Need upgrade due to expansion

AVLON YOUR ONE STOP SHOP

We offer a comprehensive turnkey solution to address your wastewater challenges, encompassing everything from innovative design engineering and meticulous fabrication to expert civil construction, precise manufacturing, seamless installation, and thorough commissioning. Additionally, we ensure regulatory compliance by securing DENR discharge permits, and our commitment extends beyond project completion, with dedicated after-sales support, technical assistance, and readily available spare parts to guarantee the long-term success of your wastewater treatment system.

OUR OFFERING

UNLOCKING THE BENEFITS OF AN UPGRADE

Elevate Compliance Standards: In adherence to DENR's DAO 2016-08, stringent effluent standards, now incorporating mandatory bio nutrient removal, are driving the need for wastewater treatment plant upgrades. Meeting these heightened discharge standards is the foremost motivation for enhancement.

Optimize Cost Efficiency: When your existing wastewater treatment plants have served for many years and are no longer cost-efficient, a holistic upgrade using Avlon's IFAS technology becomes a more cost-effective solution. This modernization approach involves replacing outdated systems, ensuring both operational efficiency and financial prudence.

Sustainable Energy Savings: Energy costs constitute a significant portion of a wastewater treatment plant's operational expenses. In the face of steadily rising energy prices, optimizing energy consumption is paramount for both environmental stewardship and economic viability. Avlon's IFAS technology offers energy-saving capabilities that can bolster the overall sustainability of your plant.

Efficient Space Utilization: Business growth often leads to overloaded wastewater treatment plants, necessitating expansion. However, space constraints can pose challenges. Avlon's IFAS technologies mitigate this issue by reducing the footprint required for expansion, ensuring that plant capacity upgrades remain achievable even in limited space scenarios.

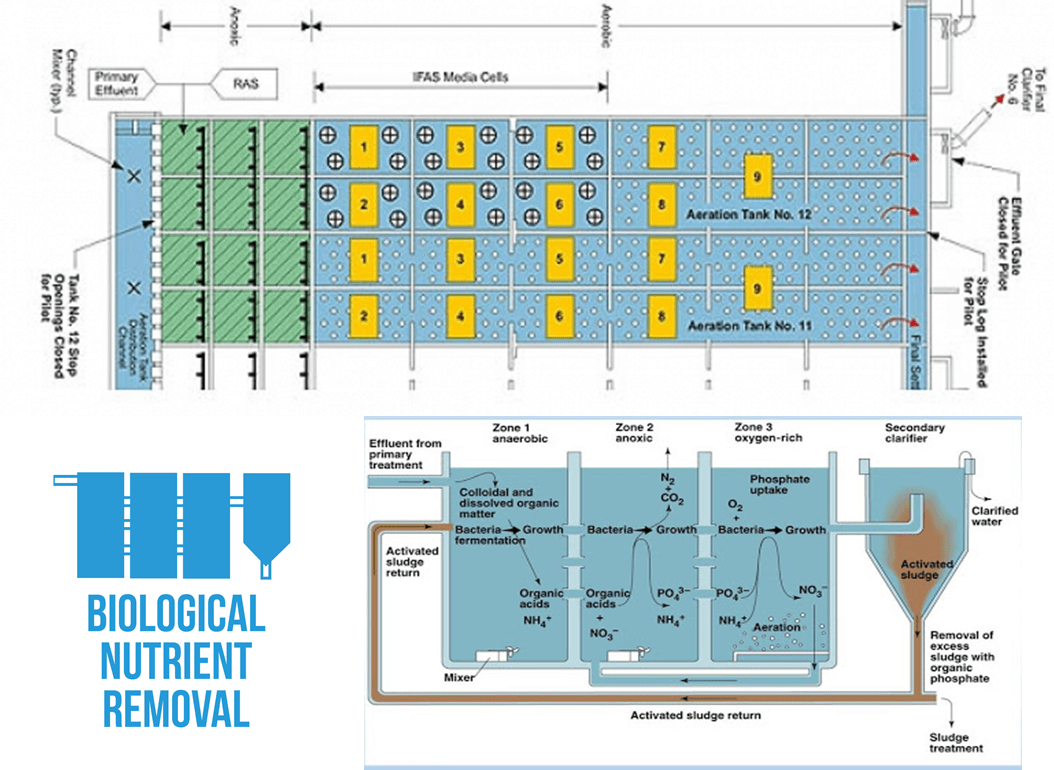

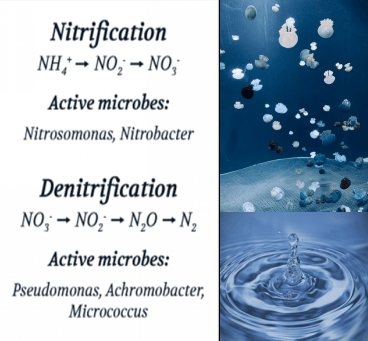

BNR (BIO NUTRIENT REMOVAL) STP PROCESS

bioifas incorporates two processes: nitrification and denitrification. Nitrification is the conversion of ammonia to nitrate and denitrification is the conversion of nitrate to nitrogen gas. Biological nitrogen removal requires an aerobic zone for converting ammonia to nitrate and an anoxic zone for converting nitrate to nitrogen gas. For best performance in terms of nitrate and nitrite removal, low DO must be maintained. Anoxic basins should be maintained with ORPs less than +50 mV but greater than -200 mV. Bioifas functions well between 10°C and 40°C.

Bioifas contains fasting-acting and robust denitrifying bacteria that remove nitrate from municipal and industrial wastewater treatment processes. It increases start-up speed, improves denitrification stability, shortens recovery time after upsets, and reduces the risk of non-compliance.

MANUFACTURED IN PHILIPPINES - YOUR BENEFIT

PRODUCTS ARE IN HIGH QUALITY AND LOCALLY MADE WITH AFTER SALES SERVICE SUPPORT

Your benefit – Avlon works with reliable and reputable suppliers that are known in the industry and are available in the Philippines. We fabricate and manufacture our product locally and we welcome clients to visit our site in Batangas. In Avlon, we take pride in our extended support to our clients from technical, repair and spare parts inquiries. We are just a call away and our engineers will be there at your service anytime and anywhere in the country.

PRODUCTS ARE IN COMPLIANCE WITH DENR STANDARDS AND LOCAL GOVERNMENT POLICIES

Your benefit – Avlon stands guarantee to our products. We make sure that we meet RA 9275 clean water act & RA 8749 clean air act.

PRODUCTS ARE FULLY AUTOMATIC

Your benefit – No skilled operator required. Less manpower cost and less maintenance cost.

PRODUCTS HAVE ENERGY SAVING DEVICES

Your benefits – Avlon design incorporates energy saving devices in every equipment and this helps clients to reduce their electrical usage, chemical consumption and other utility cost in a daily basis.

CUSTOMIZED DESIGN

Your benefit – As Avlon knows that every requirement is unique and varies on different factor such as, industry, space, budget and others, we customize our solutions based on what our client needs.

ROBUST DESIGN

Your benefit – In Avlon, quality is our utmost priority. Avlon makes sure that your investment is worthy. Every equipment in our product have a standby system providing redundancy in design and hence helping you to have a trouble-free operation and less maintenance

MODULAR DESIGN

Your benefit – Avlon works in every space available and provided by the client. It comes in modules and it requires less time for installation. It can also be transferred from one place to another as it comes in such a way where client has the options to bring it and use it should there be a change in location.

EXPERTISE IN MECHANICAL ENGINEERING AND PROJECT MANAGEMENT

Your benefit - Avlon has a pool of experts in all engineering aspects from local to international certified engineers and have a wide range experience in our product line and project management. Apart from that, our team is composed of highly skilled workers and professionals’ individuals.

NO / MINIMAL CIVIL WORKS

Your benefit – Avlon provides equipment that are modular and plug and play, in which our client can save money in overall cost in NO up to minimal civil works,

ONE STOP SHOP AND END TO END SOLUTION

Your benefit – Avlon is not just a supplier. We are partners. Avlon works hand in hand together with our client from design engineering, fabrication and manufacturing, installation, commissioning, DENR and DOLE permits up to after sales technical support and spare parts supplies.

-

Upgrade of existing STP for BNR to achieve nitrification.

-

Compact - Doubles the capacity STP without changing the footprint.

-

No Chemical Requirements.

-

Very Low Capital Cost.