- Home

- About Us

- Products

WATER TREATMENT

-

Bio floc TM

-

Bio ifas TM

-

Eco floc TM

-

Eco Chem TM

AIR TREATMENT

-

Wet pack TM

-

Wet turi TM

-

Dust bag TM

-

Dust clo TM

STEAM BOILERS

-

Pack Max TM

-

Pax Max TM

-

Fire Max TM

-

Fire Max TM

-

- Buisness with us

- Career with us

- Knowledge Base

- Contact Us

HARNESSING ADVANCED WATER TREATMENT TECHNOLOGIES

Electrocoagulation: Efficient Water Conditioning

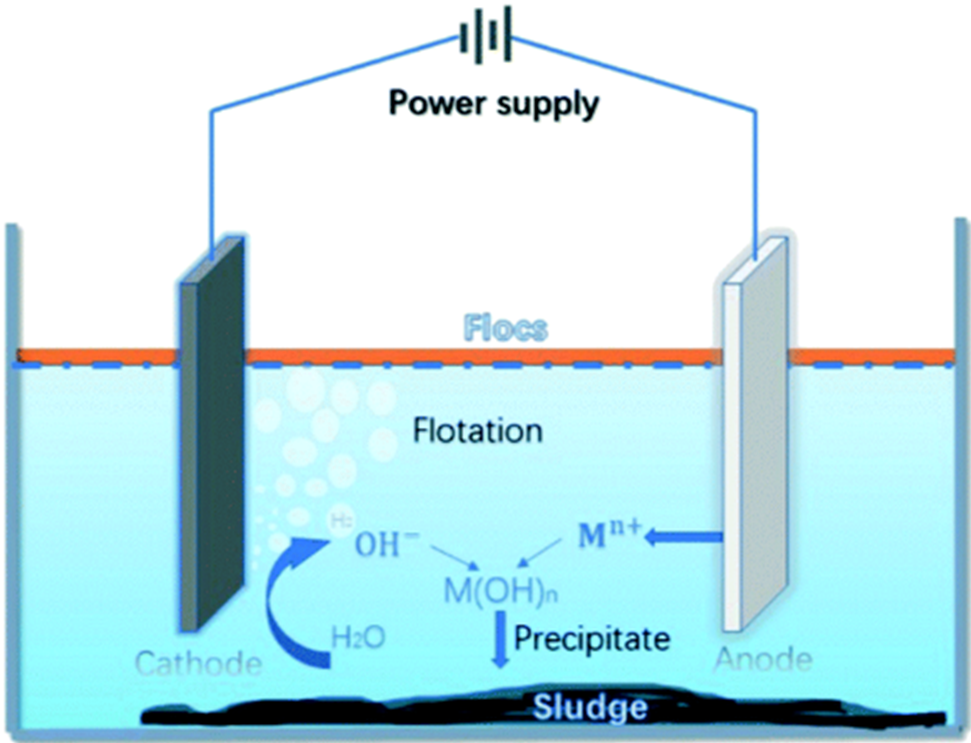

Electrocoagulation represents a cutting-edge approach to water treatment that draws from the principles of chemical coagulation but with a dynamic twist – the application of electrical energy. In an Electrocoagulation reactor, a pair of electrodes, one anode, and one cathode, create an electrolytic cell. When a specific voltage is applied, a sequence of chemical reactions unfolds. The anode, whether aluminum or iron, initiates oxidation processes, generating essential ions like Al3+ or Fe3+. As water traverses the electrocoagulation cell, a multitude of concurrent reactions takes place. Metal ions are introduced into the water, while hydrolysis at the cathode yields hydrogen gas and hydroxyl groups. Simultaneously, electrons drive the destabilization of surface charges on suspended solids and emulsified oils. The result? The formation of substantial flocs that capture contaminants, including suspended solids, heavy metals, and emulsified oils. These flocs are then efficiently removed in downstream processing steps.

Dissolved Air Flotation (DAF): Precision Contaminant Separation

For the meticulous separation of contaminants from water laden with flocs, we employ the versatile Dissolved Air Flotation (DAF) systems. Here, micro air bubbles take center stage, facilitating the separation process. As water flows into the skimming tank under atmospheric conditions, micro-bubbles ascend, carrying suspended solids to the tank's surface for swift removal. Avlon's DAF systems offer a dual benefit by significantly reducing sludge volume through initial thickening, resulting in remarkable cost savings for our customers. This water treatment journey encompasses a spectrum of processes, including ionization, destabilization, oxidoreduction, electrolysis, free radical generation, electromagnetic field formation, and the crucial breaking and separation of emulsions. Through the seamless integration of electrocoagulation and DAF technologies, we deliver water treatment solutions that excel in efficiency, sustainability, and performance.

ONE STOP SHOP

We take care of design engineering, fabrication, manufacturing, installation, commissioning, securing DENR discharge permits and up to after sales with technical support and spare parts.

OUR OFFERING

STREAMLINED OPERATIONAL PHILOSOPHY

Our Electrocoagulation system is engineered for operational simplicity and efficiency. Housed within a modular intermodal cargo container, it's a plug-and-play solution that can be seamlessly integrated into your facility, whether above ground or underground.

THE PROCESS UNFOLDED:

Water Intake: The journey begins with the Sump Pump, drawing water from the Sump Pit and directing it into the system.

Chemical Enhancement: As water flows through the chemical enhancement piping, pH, ORP (Oxidation-Reduction Potential), and conductivity are expertly adjusted to optimize treatment conditions.

Quality Assurance: Sensing probes ensure that pH, ORP, and conductivity levels are precisely where they need to be.

Flow Control: The water then encounters a flow control valve and a flow meter, ensuring the flow rate is regulated for optimal performance.

Electrocoagulation: The heart of the system lies within the Electrocoagulation Chamber, where water is meticulously pumped between metal plates charged with DC current. This controlled electrochemical process kickstarts pollutant removal as suspended contaminants bond together, forming larger, easier-to-remove masses.

Coalescing and Flocculating: The treated water proceeds to the Coalescing/Flocculating Tank. Here, bonded contaminants coagulate and flocculate out of the water, while emulsified oils are efficiently separated and removed via the Oil Decanter Cone.

Holding and Transfer: Product water moves to the Holding Tank, awaiting transfer via the Transfer Pump.

DAF Precision: The effluent water then undergoes Dissolved Air Flotation (DAF) treatment. Emulsified petroleum elements rise to the water's surface, while heavier solids settle to the tank bottom. Separated contaminants are directed to a sludge accumulation tank, while the purified water proceeds to a separator tank for the final removal of any remaining floc.

Efficient Powerhouses:

Our system features two high-capacity centrifugal pumps designed for peak performance, with operational control at your fingertips. A consolidated control panel empowers operators to effortlessly manage and adjust critical system variables. Whether manual or automatic operation is preferred, our system caters to your specific needs, with the option for remote operation for added convenience.

In summary, our Electrocoagulation and DAF system ensures seamless, precise, and efficient water treatment, making it an invaluable asset for achieving water quality goals, regulatory compliance, and sustainable water management.

SAND FILTERS, MULTIMEDIA FILTERS AND ACTIVATED CARBON FILTERS

AVLON filter makes use of the most advanced known technology for achieving high rate filtration at minimum cost. The filter can be adapted to any water condition of turbidity, colour or odour. To reduce the concentration of solids below 1 mg/l TSS and colloidal silica below 0.05 mg/l consistently and independently of influent quality even after heavy rains, up flow deep bed media filters of AVLON are cost-efficient alternatives to the conventional silica removal process by lime-fed clarification and down flow sand filtration which also take multiple times the footprint.

The under drain nozzles are specially designed to allow back washing with air and water. The nozzles slots are sized to prevent the escape of the media; the nozzle head is attached to a tube slotted at its lower section through which air is introduced. Depending on the media that is used, nozzles can be provided with slot openings ranging between 0.2 and 2.0 mm.

-

Odour free

-

No chemicals required

-

Minimum sludge

-

Noiseless continuous process

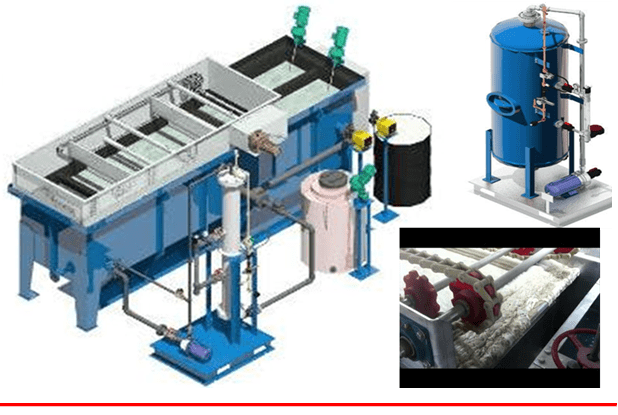

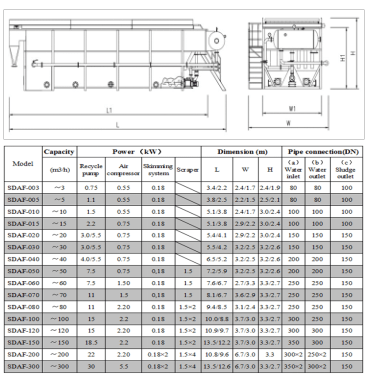

DISSOLVED AIR FLOTATION

The AVLON Dissolved Air Flotation (DAF) systems use chemical pretreatment and micro air bubbles to separate contaminants from water. Our DAF is the perfect combination of DAF System and Sedimentation process and implements solid-liquid separation most efficiently. When this water is released into the skimming tank under atmospheric conditions, micro-bubbles form and carry the suspended solids to the surface for removal.

AVLON DAF allows plant operations to process 6 to 10 times less sludge by thickening first, meaning sludge treatment and disposal are decreased dramatically, resulting in a significant savings for customers.

-

Color removal

-

Low operating cost

-

Requires low power

-

Low capital cost

MANUFACTURED IN PHILIPPINES - YOUR BENEFIT

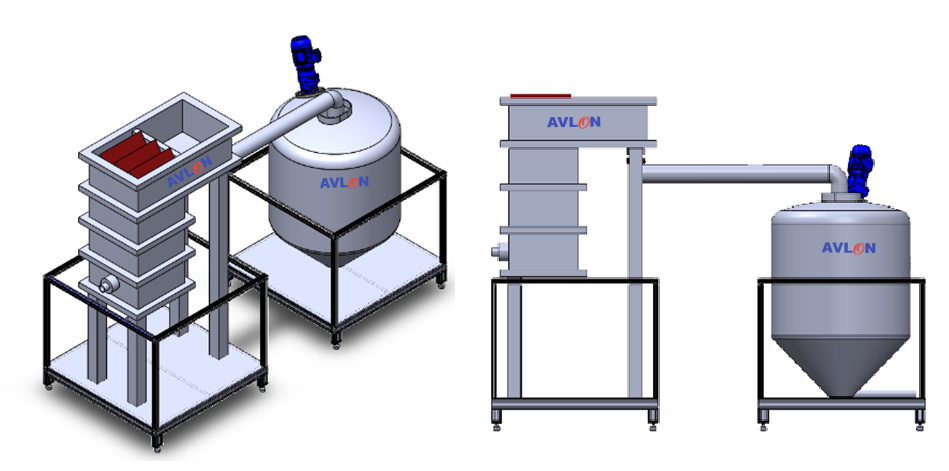

Ecofloc is industrial waste water treatment packaged system where all wastewater treatment equipment is completely pre-installed in containers. The modular container system with the various components of a waste water plant is adjusted to customer requirements and can be easily transported by land and sea. All the waste water treatment equipment is pre-installed and factory tested.

Ecofloc is designed for waste water treatment, sludge treatment and industrial water treatment for different medium and large-scale applications. Only a solid base or foundation is needed on which to place the containers. The solution is modular, fully automatic plug & play and can be tailored to the specific project requirements. It can be designed as complete waste water treatment plants or hybrid systems, depending on the requirements.

Ecofloc is constitutes a large range of skid-mounted systems industrial waste water treatment in compliance with DENR DAO 2016-08 Regulation and the units use well-known and efficient technologies to produce high quality water: coagulation, flocculation, lamella clarification, pressure sand filtration, and disinfection. All of AVLON products and components are sourced from reputable suppliers and OEMs locally and internationally, providing our customers with the highest quality products that achieve the highest possible water quality.

-

Less space required

-

Consistent & reliable results

-

Suits for remote locations

-

Reuse of water for multi-application