Geometry of a Cyclone as per dust collector manufactures Philippines

As per dust collector manufactures Philippines an cyclone separators operate by integrating centrifugal force, gravitational force, and inertial forces to remove fine particles suspended in air stream or gas stream. Our separators use cyclonic action to separate particulates from a gas stream. Typically, particular matter enters the cyclone separator at an angle (perpendicular to the flow stream, tangentially, or from the side), and is then spun rapidly.

A centrifugal force is created by the circular airflow that throws the particulate towards the wall of the cyclone. Once the particular matter hits the wall, it falls into a hopper below. “Clean” exhaust is then either blown through or recirculated to be filtered again. It is important for dust collector manufactures Philippines to keep in mind that the centrifugal force (Fc) a cyclone generates on a particle is related to the tangential air velocity (vt), particle mass (m), and the particle’s radial distance from the cyclone wall (r) by the function: Fc = m * Vt 2/ r.

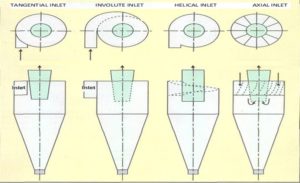

An appropriate design of the inlet type has been proved to be an effective approach to improve the performance of a cyclone separator. Decreasing the curvature radius is beneficial for enhancing the stability of the inner flow field and improving the separation precision. Cyclone inlet design is of critical importance to dust collector manufactures Philippines for both efficiency and pressure drop. Inlets should be such that incoming gas does not have interference with the mass of gas already rotating in the annulus and suppression of vortex. There are four different types of cyclone inlet design.

TANGENTIAL INLET AS PER DUCT COLLECTOR MANUFACTURES PHILIPPINES.

In these types of design, the outside edge of the inlet duct is tangent with the cyclone body. The tangential inlet generates the swirling motion of the gas stream, which forces particles toward the outer wall where they spiral in the downward direction. Tangential inlets with nonexpanding inlet vanes result in ½ pressure drop of the same cyclone without vanes whereas expanding vanes reduces pressure drop by ¼ th.

The advantages for dust collector manufactures Philippines include low pressure drop, suitable for the lowest possible inlet velocities, most robust and versatile mechanical design and lowest cost. Whereas the disadvantages are that these designs may require a greater cyclone diameter and/or height for high capacity cyclones to prevent erosion on the outside of the cyclone outlet pipe with abrasive particulate and high particle loadings. Higher inlet velocity (and subsequent body erosion if the particulate is abrasive) may be required to achieve the same collection efficiency as the involute design.

INVOLUTE INLET

In an involute inlet the outside edge of the inlet duct is positioned outside of the cyclone radius and is tapered into the body over some rotation. Involute inlet minimizes the interference between these gas streams. Use of multiple involute inlets has advantage that for the same inlet area and height, inlet width is reduced. Involute inlets are useful for making compact high capacity designs and it also help to reduce erosion when there is high particulate loading. Theses design also increases collection efficiency when increasing inlet or outlet velocity are not desirable. However, these types of design are more expensive for dust collector manufactures Philippines and difficult to fabricate and also increases pressure drop. If you are designing a cyclone were nozzle loading is significant then involute inlet is less robust.

HELICAL INLET

In this type of design, the roof of the inlet and cyclone spirals downward. Most commercial Cyclones do not have helical type inlets. May prevent solids build up on roof surfaces if the material is stick but at the same time its more expensive and have lower Efficiency.

AXIAL INLET

For the case of an axial inlet, where fluid enters the cavity through the center of the upstream disc, the flow structure depends on the magnitude of the mass flow into the cavity. These designs are good when arranged in a common plenum as in multi clones and also lend themselves to economical mass production. It has Lower collection efficiency and the wear on vanes can adversely affect collection efficiency and reduce pressure drop

DUCT CONNECTION TO INLETS

Installation of cyclone dust collectors should follow industry-accepted criteria. To assure proper performance, intake duct-work must be designed so that sufficiently high velocities are maintained for particulates to remain airborne as they are conveyed to the cyclone. For maximum cyclone efficiency, it is important that ductwork be properly engineered.

When possible,dust collector manufactures Philippines always keep the elbows or bends in ductwork upstream of the cyclone should direct entering air in the same rotational direction as the cyclone itself. Static electricity buildup has detrimental effects on cyclone performance. Static charge buildup increases with grain load. Collectors must be properly grounded to eliminate dust buildup on their internal surfaces. Installation should include a vortex-breaking receiver hoper and air lock. This equipment balances the airflow leaving the top of the reverse flow cyclone with the entering airflow.

Avlon Inc is the best dust collector manufactures Philippines when it comes to dust collectors. Keep visiting www.avlon-php.com for more information. We have the best quality and customer service with affordable price