Sewage treatment plant suppliers in Philippines and their system Automation process

The importance of automation in chemical dosing is very clear to sewage treatment plant suppliers in Philippines. The particulate impurities commonly called suspended solids cover a broad size range. Smaller sized particles, do not readily settle and treatment is required to produce larger particles that are more amenable to removal.

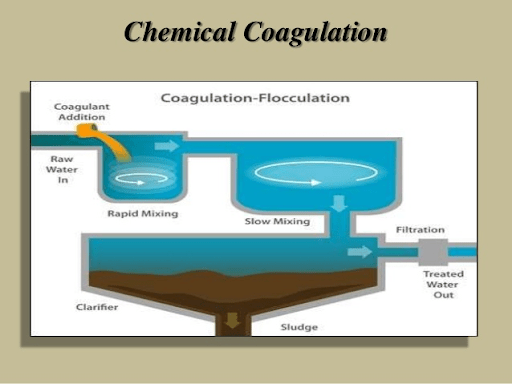

These smaller particles are often called non-settleable solids or colloidal matter. To remove colloidal particles the sedimentation step is usually preceded by a chemical process known as coagulation. Coagulants with charges opposite to those of the suspended solids are added to the water to neutralize the negative charges on dispersed non-settable solids such as clay and organic substances. The particles gather together to form larger particles in the flocculation process. When pieces of floc clump together, they may form larger, heavier flocs which settle out and are removed as sludge sewage treatment plant suppliers in Philippines.

Coagulant chemicals used by sewage treatment plant suppliers in Philippines

Chemicals used in coagulation / flocculation are referred to either as primary coagulants or as coagulant aids. Primary coagulants are used to cause the particles to become destabilized and begin to clump together. The purpose of coagulant aids may be to condition the water for the primary coagulant being used, to add density to slow-settling flocs or toughness so the floc will not break up in the following processes.

Aluminum sulphate, ferric chloride, ferric sulphate and polyaluminum chloride are the primary chemicals used by sewage treatment plant suppliers in Philippines to treat drinking water. These chemicals work by using the positive charge of aluminum or iron to neutralize the negative charge on the dissolved compounds and suspended particles in the water. This causes the formation of large particles, which settle quickly.

Powdered activated carbon (PAC), a coagulation aid, are also used sewage treatment plant suppliers in Philippines in coagulation cells to enhance the removal of taste and odour compounds, and remove some organic carbon. In water treatment plants, aluminum sulphate is a commonly used coagulation chemical, followed closely by ferric chloride. Polyaluminum chloride is used for specific applications, such as extremely turbid water and in-house treatment systems, because it is less sensitive to variations in water quality.

FACTORS AFFECTING COAGULATION

The optimal pH range for coagulation is 6 to 7 when using alum and 5.5 to 6.5 when using iron. For high alkalinity water, excessive amounts of coagulant may be needed to lower the pH to the optimal pH range. In these cases, it may be beneficial to use acid in addition to the coagulant to reduce the amount of coagulant needed and effectively lower chemical costs. It is important to sewage treatment plant suppliers in Philippines to determine the optimal dose for coagulation; insufficient doses will not effectively destabilize the particles and adding excessive doses can cause detrimental effects such as re-stabilization, excessive sludge production, or corrosion. Water quality parameters such as pH, temperature, and alkalinity may dictate effectiveness of the coagulation-filtration process. Let’s evaluate the three major factors which effects the chemical coagulation and flocculation process in water treatment

FACTOR 1: OPTIMIZATION OF PH

The pH will not only affect the surface charge of coagulants, but also affects the stabilization of the suspension. The effectiveness of alum, is severely affected by low or high pH. In optimum conditions, the white flocs were large and rigid, and settled well in less than 20 min. The reduction of turbidity and other parameters was observed to be good at pH 7. Iron coagulants can have an advantage relative to aluminium in this application, as operation at a much lower coagulation pH can be used to maximise the removal of dissolved organic matter and consequent reduction in the potential for THM formation by sewage treatment plant suppliers in Philippines.

For harder waters, iron coagulants are often used if coagulation pH values of 8.0 or more occur – such pH values would not be appropriate for aluminium coagulants unless separate acid dosing were applied. Increasing the dose of metallic salt will further depress the pH but will result in a very undesirable increase in the soluble metallic content of the water, which will carry through the filters to supply. Dosing with a strong mineral acid, such as sulphuric acid, will depress the pH without the unwelcome increase in the soluble metallic content of the water. Lime is the most widely used alkali for coagulation pH control. It is most commonly delivered to site in its hydrated powdered form, stored in silos, and then dosed as a slurry. Lime dosing systems can be problematic, but reliable operation is achievable if good design practices are followed.

FACTOR 2: OPTIMIZATION OF MIXING TIME

In coagulation process, rapid mixing is used by sewage treatment plant suppliers in Philippines to spread out the coagulant throughout the turbid water. In flocculation process, slow mixing is a key part to get most favorable performance. Adequate time must be provided to allow production of particles of sufficiently large size to permit their efficient removal in sedimentation process. The turbidity reduction was observed to be prodigious at high rpm, i.e., 100–30 rpm at all pH ranges. When using sodium aluminate in conjunction with aluminium sulphate the two reagents must never be mixed before addition to the water. The sodium aluminate must be added to the water a short time ( 0.5 to 2 min.) before the alum.

When used as coagulant aids polyelectrolytes should be dosed after the inorganic coagulant. Sufficient delay time (from one to several minutes) should be allowed following the addition of the inorganic coagulant to allow `microflocs’ to form before dosing the polyelectrolyte. In addition to turbulence at the point of injection, it is also important to allow sufficient delay time following polyelectrolyte addition to permit mixing and/or reaction before the subsequent solids-liquid separation.

Delay times of approximately one minute are generally satisfactory, but the required time will depend on the hydrodynamic conditions obtaining on the plant. Timing of the addition of onditioning chemicals and coagulants, as well as of coagulant aids, has been found to be of great importance and is usually critical to effective clarification performance, satisfactory filter performance, as a consequence, and hence the quality of the final water.

FACTOR 3 : EFFECT OF COAGULANT DOSE

Coagulation dosage is one of the most important factors that have been considered to determine the optimum condition for the performance of coagulants in coagulation and flocculation. Essentially, insufficient dosage or overdosing would result in the poor performance in flocculation. Therefore, it is significant to determine the optimum dosage to minimize the dosing cost and sludge formation and also to obtain the optimum performance in treatment.

The optimum alum dosage was lower (1 g L−1) which was the lowest required dosage obtained the highest turbidity removal. Generally, aluminum and iron salts are rapidly hydrolyzed in water to give a range of products including cationic species which can be absorbed by negatively charged particles and neutralize their charge. This is one mechanism whereby particles can be destabilized, so that flocculation can occur. Overdosing can disrupt this phenomenon, therefore, fairly precise control of coagulant dosage should be considered by sewage treatment plant suppliers in Philippines in water treatment plants.

NEED FOR AUTOMATION:

Coagulant should be dispersed rapidly (ideally in a few seconds) and effectively throughout the process flow. The effectiveness of dispersion is supported by dilution and application at a point of turbulence. The order in which coagulant and pH adjustment chemical are added may impact on floc quality. In the case of low alkalinity waters, typical practice is to dose alkali before coagulant to avoid loss of alkalinity and ensure that the optimum coagulation pH is reached as rapidly as possible. Flocculant aid (e.g. polyelectrolyte) should be dosed a few minutes after coagulant has been dispersed.

There is benefit in having flexibility in the location of the flocculant aid dosing point: a longer delay between coagulant and polyelectrolyte dosing can be beneficial if water is cold. Accurate pH measurement in waters of low ionic strength is supported by the use of sensors with a flowing reference junction, using sensors with a good track record in this application and ensuring that a good electrical earth is present in the system.

Automated control of chemical coagulant dosing has not been in widespread use in Philippines up to now with some notable exceptions in recent years. Avlon Inc, having wide experience in water treatment can design customized chemical doing automation system to meet your project requirements. For more information visit us at www.avlon-php.com