Boiler supplier Philippines- Avlon Introduction:

We as a Boiler supplier Philippines recommend our customer to best boiler operational practice that constantly looks into ways to improve operating efficiency. One of the ways is by incorporating an Economizer in the flue gas path. An economizer is basically a Heat exchanger unit to recover heat from flue gas coming out of any steam boiler and in turn heat the feed water. The economizer is a fuel saving proposition with an attractive payback as it utilizes the heat from the flue and thus saves fuel from getting wasted.

The number of Boiler supplier Philippines that use flue gas economisers effectively to reduce energy costs is far fewer and the main reason lack of detailed awareness, rather than any unwillingness to embrace the technology. Reducing energy costs with economisers can reduce fuel usage for the same boiler output, and can typically offer businesses fuel savings of between 4% and 6% with a return on investment between 6 to 18 months. We will discuss in this paper the working principle and some calculation on how much money you save by incorporating and Avlon Economizer in any of your boiler fired on any fuel of any capacity.

When Should You Install an Economizer:

The stack temperature should be as low as possible, since it carries all the heat from the fuel. However, it should by the Boiler supplier Philippines that not be so low that water vapor from exhaust condenses on the stack walls. This is important in fuels containing significant sulphur, as low temperature can lead to sulphur dew point corrosion and acid attack effects on metallic parts in the flue gas path. A stack temperature greater than 150ºC indicates potential for recovery of waste heat.

It also sometimes indicates the fouling and scaling of heat transfer/recovery equipment. Boiler users must monitor stack temperature and compare it with design value. When it has increased over time, maintenance of heat transfer surfaces is called for. If the design value itself is high, the stack temperature can be reduced by installation of Economizer. Remember, for every rise of 6ºC in boiler feed water temperature through waste heat recovery would offer about 1% fuel savings.

How Do Economisers Work?

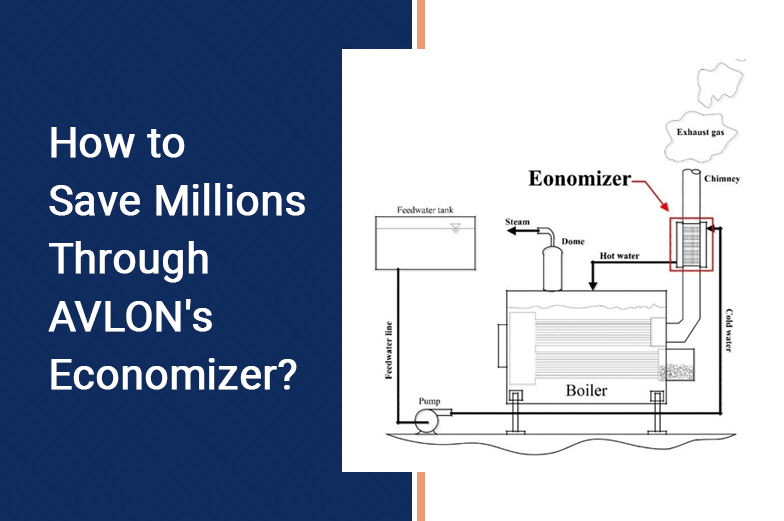

Installed between the boiler and chimney, economisers operate on the principle of heat exchange, salvaging the boiler flue gases to pre-heat the boiler feed water. This reduces the amount of energy that is required to heat the boiler feed water to operating temperature. Usually constructed from carbon steel, the economiser design incorporates finned tubes, containing the boiler feed water, that run perpendicular to the flow of hot gas. These finned tubes transfer heat from the flue gases into the water flow as per Boiler supplier Philippines. This process lowers the flue gas temperature while the feed water temperature is increased.

Economizers are available in a wide range of sizes, from small coil-like units to very large waste heat recovery boilers. The rectangular economizer uses high frequency resistance welded finned tubes to recover heat from the flue gas that flows counter-current to the boiler feedwater. AVLON Economizer are of compact design with the use of MS Fins which increases the extended heating surface. The unique design and special shrink fitting process of M S Fins on the tube are tested. Casting on bends takes total care of protecting bends from erosion and puncturing.

AVLON Economizers will be custom engineered, for your application, by our industry leading thermal design experts in Boiler supplier Philippines to maximize heat recovery. Every aspect of the design is chosen with the goal of providing a product that will perform trouble-free for many years. From selecting the right metallurgy for the application to the right enhanced surface and tube layout, based on fuel and fouling concerns, paying close attention to erosion, corrosion and vibration concerns, you can be rest assured that our heat recovery unit will be ideally suited for your application.

FUEL SAVING CALCULATION

Steam Generated : 8 TPH

Steam Pressure : 10 kg/cm2 (g)

Steam Temperature : 1800C

Enthalpy of steam at 10 kg/cm2 (g) : 665 kCal/kg

Feed Water Temperature : 850C

Enthalpy of feed water : 85 kCal/Kg

Boiler Efficiency : 72.5 %

GVC of Coal : 4000 Kcal/Kg

Boiler Heat Output = steam flow rate (steam enthalpy – feed water enthalpy)

= 8TPH X 1000 Kg/hr. (665 – 85) Kcal/kg = 4640000 Kcal / Hr.

Fuel consumed = Boiler heat output / (boiler efficiency x GVC of Coal)

= 4640000 / (0.725 X 4000) = 1600 Kg / hr.

Now if we increase the feedwater temperature by 400C, then the Enthalpy of feedwater will be 125 Kcal/Kg

Therefore, Boiler heat output = 8TPH X 1000 Kg/hr. (665 – 125) Kcal/kg = 4320000 Kcal / Hr.

Therefore, fuel consumed = 4320000 / (0.725 X 4000) = 1545 Kg / hr.

Hence the fuel saved = 1600 – 1489 = 110 kg/ hr

Money Saved = 110 kg/hr. x 3.5 Peso/ kg X 23 hrs. / day X 365 days = 3,232,075 Peso / Year

For more details contact us or visit our website: www.avlon-php.com, We are one of the best Boiler supplier Philippines and its accessories in Philippines