Boiler water Treatment- Introduction

In Boiler water treatment, turbidity is a measure of the degree to which the water loses its transparency due to the presence of suspended particulates. The more sediments in the water, the more turbid the water is. The suspended particles absorb heat from the sunlight, making turbid waters become warmer, and so reducing the concentration of oxygen in the water (oxygen dissolves better in colder water). Some organisms also can’t survive in warmer water. The suspended particles scatter the light, thus decreasing the photosynthetic activity of plants and algae, which contributes to lowering the oxygen concentration even more. As such, suspended particles can clog fish gills, that results in reduced resistance to disease, decreased growth rates, and affects egg and fish larval development.

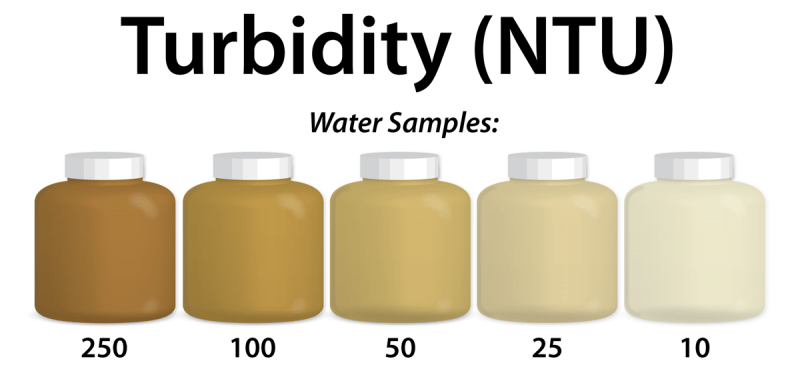

Turbidity Measurement and Acceptable Range

Turbidity is measured by an instrument called nephelometric turbidimeter, which expresses turbidity in terms of NTU (Nephelometric Turbidity Units) and is measured using a relationship of light reflected from a given sample. The turbidity of drinking water should always be less than 1 NTU. Most treated city water is less than 2 NTUs. A turbidity measurement could be used to provide an estimation of the TSS (Total Suspended Solids) concentration, which is otherwise a tedious and difficult parameter to measure.

Effect of Turbidity

Not only is cloudy Boiler water treatment ascetically unappealing, it can pose a health risk by providing food and shelter to microorganisms in the water. The suspended particles in the water can help protect pathogens from disinfectants in the water distribution system, and they can even promote their regrowth after the disinfectants are used up. Because it interferes with disinfection of drinking water, excessive turbidity levels have been associated with gastrointestinal illness. Contaminants such as heavy metals, toxic organic compounds and pesticides can become attached to suspended particles, giving them a free ride through the water distribution system. Bacteria, viruses and parasites can also attach themselves to suspended particles in water.

Boiler water Treatment of Turbidity

Boiler water Treatment should start with making sure that the well screen is properly sized and in good condition. Not only can turbidity cause problems with water quality, but grit can also damage water pumps. Generally, filtration is the last step in a process of treating this type of water. To remove turbidity, often the first step is to inject a flocculant, or coagulant aid, which allows these microscopic suspended particles to lose their positive charge and “floc” together into larger clumps. The water is allowed to settle, and is then followed by filtration to remove any suspended floc. In some cases, the water must be gently stirred or agitated in order for the floc to form. A very effective method to remove turbidity is with reverse osmosis (“RO”) or ultrafiltration (“UF”) membrane systems. RO and UF systems can reduce turbidity and produce crystal clear water less than 0.1 NTUs.

Coagulation, Chemical Feeds, Flash Mix

Turbidity reduction is best achieved when the water is run through a series of chemical and physical treatment methods before reaching the filter. The terms coagulation, flocculation, and flash mix are often discussed together. Basically, coagulation is the process of getting particulates to stick together, flocculation is when this process becomes visible, and the flash mix is the fast mixing that makes it happen.

Boiler water treatment Coagulants include alum or polyelectrolytes such as polyaluminum chloride. Some water will react better with one chemical than the other. The correct dosage is determined with jar testing and feed pump calibration. The coagulant is usually injected into the line before the flash mix, sometimes using a static mixer (a short piece of pipe with internal spiral fins). Proper mixing is important to coagulation, as is the proper dosage of the coagulant. Coagulation can start as soon as the chemical is added, but the flash mix kicks the process into high gear. The flash mix is usually aided with a motorized paddle or the water is allowed to fall (splash) into a chamber making the water turbulent.

Flocculation

Flocculation usually consists of a two-or three-stage process, and begins when the particulates start sticking together more visibly. The process still uses the motorized paddles, but at a slower rate than during the flash mix. Stage one of flocculation is fastest, with the second and third stages working more slowly and sometimes with the paddles moving in the opposite direction. This allows the particles to get heavier and help them settle to the bottom in the next part of the process, sedimentation.

Sedimentation

Boiler water treatment during sedimentation, the particles of dirt settle to the bottom of the basin. The sedimentation basin is the last step before the filters, so sedimentation must work effectively. The key to good sedimentation is having enough area and/or time for settlement and, subsequently, good sludge removal.

Sludge at the bottom of the tank is usually scraped with a slow-moving blade to a sump and drain. Some settlement basins have a cone-shaped bottom to direct the sludge to a drain. It still may be necessary to drain the sedimentation basin and clean the sludge every five to 10 years, depending on the water quality. Some sedimentation basins have tube settlers (slanted tubes that help with contact area and time for settling). Sometimes baffling is used or can be added to help the sedimentation time.

Filtration

Filtration is the last stage in turbidity control before the clear well. Most filters can handle a wide range of turbidity, but don’t leave all the work up to them. The other processes—chemical mix, flash mix, coagulation, flocculation, and sedimentation—must work optimally for the life of the filters and to provide a safety factor or cushion for lower turbidities. The less turbidity going into the filters means longer filter runs and longer filter-media life, which saves money.

AVLON stands guarantee to our products. We make sure that we meet Philippines DENR RA 9275 Clean Water Act under its latest Regulation DAO 2016-08 on general effluent Standard. AVLON filter makes use of the most advanced known technology for achieving high rate filtration at minimum cost. The filter can be adapted to any water condition of turbidity, colour or odour. Avlon is best when it comes to water treatment plans and other clean water products. Know more about us www.avlon-php.com