Metering Pump for chemical dosing

Treating wastewater is a complicated process involving critical steps that must be performed to exact criteria by highly technical equipment. An experienced sewage treatment plant manufacturer in Philippines knows very well that only effective when the proper chemicals are used to treat the water, and these chemicals can cover a wide range of pH levels, viscosities, material compatibilities and handling characteristics.

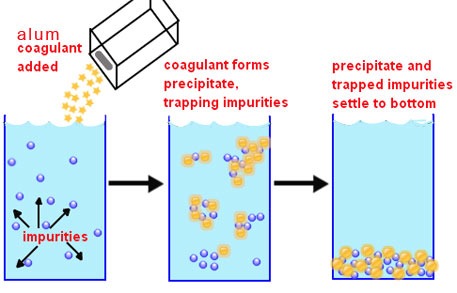

Municipal water treatment plant applications require long-term, trouble-free operation with pumps and other equipment operating essentially non-stop from the moment they are installed. The large variety of chemicals used in municipal water processing presents a number of application requirements, which must be addressed in achieving this goal. These chemicals include: sodium hypochlorite, sulfuric acid, polymers, ferric chloride, sodium bisulfite, lime, alum, potassium permanganate and ammonia.

Sizing & Selecting Metering Pumps

The first step is identifying the required capacity in terms of flow rate and discharge pressure. Avoid over-sizing a metering pump. Size the pump so the maximum expected flow rate is 85 percent to 90 percent of the pump’s total capacity. This ensures additional capacity if needed. The minimum capacity should never be less than 10 percent of the pump capacity to maintain accuracy.

Next, ask questions to the sewage treatment plant manufacturer in Philippines about the construction of the pump. Metering pumps are available in a variety of materials. Among the more important selection criteria is resistance to corrosion, erosion and solvent action. Solvent-based chemicals may dissolve plastic headed pumps. Acids and caustics may require stainless steel or alloy liquid ends. Abrasive slurries can erode equipment unless the right pump construction materials are used.

Some chemicals in the water treatment process are viscous or form a slurry. Others release gas during the treatment process. The sewage treatment plant manufacturer in Philippines should recommend special “liquid ends” to accommodate these applications. Whereas standard metering pumps handle clear liquids with viscosities ranging from water-like to 1500 cps, using liquid ends increases viscosity capabilities to 5,000 cps and light suspensions. For true slurries or higher viscosity, tubular diaphragm heads can be employed which permit pumping chemicals to 20,000 cps or slurries containing up to 10 percent solids. Liquid ends also will vent accumulating gases automatically.

Protection against leaks is another area where the sewage treatment plant manufacturer in Philippines should seek expert advice. Double diaphragm heads featuring leak detection and alarms are available. Where leaks must be detected immediately, these devices are invaluable. Example applications include those where contact between the process fluid and the pump hydraulic fluid cannot be tolerated or where, due to the toxic or hazardous nature of the fluid being pumped, leakage cannot be tolerated.

Ask questions about pump driver selection to the sewage treatment plant manufacturer in Philippines. This selection must be based on matching available utilities, which may include electric, air, gas or other means of driving the pump. Identify hazardous area requirements when selecting the driver. Certain types of dust can ignite and so can many fumes and vapors.

Tell the chemical metering pump provider if the pump is indoors or outdoors. The motor should be sheltered from direct sunlight. Pumps will operate in freezing temperature provided the fluid to be pumped will not freeze and the correct lubricants are selected. Freeze protection and heat tracing may be required. Corrosive environments may require a special coating on the equipment.

Sewage treatment plant manufacturer in Philippines had outlined below commonly used chemicals in wastewater treatment applications and their characteristics are outlined below.

Sodium hypochlorite: Widely known as bleach, this liquid is most commonly used for disinfection at the treatment plant. This chemical is one of the most difficult to handle because it corrodes most metals it comes in contact with, and it cannot be mixed or stored with ammonia or other acids, organics and reducing agents used at the plant. It is also difficult because of its tendency to off-gas, which can cause metering pumps to become gas-bound. To prevent this, special vent valves are available for diaphragm pumps. Peristaltic pumps, which do not allow this phenomenon to occur, also can be used.

Sulfuric acid: Used for pH adjustment, this chemical is provided either as a concentrate or dilute. Concentrated solutions can be handled in many situations with cast iron, steel materials or Alloy 20, while dilute solutions require plastics such as PVC or Kynar.

Sodium hydroxide: Also used for pH adjustment, this chemical is often provided in solution strengths from 25 to 50 percent. Metering pump elastomers, such as Viton (a material often used for O-ring seals within a metering pump), are not compatible with sodium hydroxide, so they require special care. Especially in higher solution strengths, this chemical tends to gel in the pump if the pump is idle for a period of time. Flush valves or special pump heads can assist with this issue.

Sodium bisulfite: This is one of the most commonly used dechlorinating agents at treatment plants. A mixer is usually required to keep this chemical in solution in the metering pump supply tank. Suitable materials for this chemical include plastics, such as PVC and Kynar, and metals, such as 316 stainless steel.

Emulsion polymer: Fed as a coagulant to assist the dewatering equipment within a wastewater treatment facility, this chemical is shear-sensitive once hydrated and is often extremely viscous. Diaphragm pumps with high-viscosity head designs or peristaltic pumps are often required.