Sewage treatment plant suppliers – Chemical Dosing System

DENR are increasingly imposing restrictions on the levels of phosphorous to sewage treatment plant suppliers in the discharge from sewage treatment plants. As per Philippines DENR RA 9275 Clean Water Act under its latest Regulation DAO 2016-08 on general effluent Standard the Phosphate content should be below 1 Mg/L.

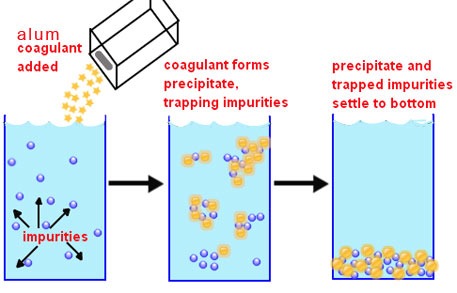

When sewage is treated biologically, some of the phosphate is utilized by the bacteria. However, to ensure final effluent levels are below 1 mg/l, suitable chemical reagents are added to assist in the precipitation of the excess phosphates via a dosing unit.

Avlon Inc in Philippines is a sewage treatment plant suppliers who has developed a CHU (Chemical Dosing Unit) which has closed loop feed forward control of inlet dosing systems for the removal of phosphate having are dual channeled pH controllers providing either relay or proportional pulse outputs to drive chemical metering pumps. Dosing iron salts at the front end of a works requires a level of pump control to ensure that the pH of the influent does not become too acidic as this has a detrimental effect on the nitrifying process.

A chemical dosing skid is the most effective way to dispense chemicals, using at least two peristaltic or metering pumps attached to pipe manifolds encased in a cabinet. One pump act as a duty standby to ensure the dosing process is uninterrupted should a wearable component need to be serviced. Programmable features make it the most adaptive pH controller available. These all have manual stroke length adjustments which allow their output to be adjusted between 10 to 100%. There are also various sizes available ranging from 0.3 to 14.0 l/hr. which covers all sewage treatment plant suppliers requirements.

The advantage of determining the phosphate level at the inlet is that the dose rate of the iron or aluminium salt can be calculated and the dosing pump system controlled using the combined flow and phosphate concentration. The combined output generated allows the operator to adjust the dosing pumps for site-specific conditions that allow the ‘P to Fe’ ratio to be adjusted until it is optimized. This optimization requires the monitoring of the final effluent to ensure that the phosphate levels are within the DENR consent and once the optimization has been done by sewage treatment plant suppliers for there is no need to further monitor the final effluent.

sewage treatment plant suppliers- CHU for efficient Dosing system:

All of Avlon CHU has two chemical holding tanks that can be isolated to allow for maintenance. Chemical passes out of the holding tanks through a series of isolation valves to the inline filters. These filters remove debris from the chemical, which can reduce the pumping efficiency, or block up valves upstream of the pumps. These filters need regular cleaning by sewage treatment plant suppliers , and are the most common cause of problems within the dosing system. If they become blocked the pump is not able to deliver the required dose rate. It is advisable to clean both filters prior to calibrating a pump. Once the chemical has been through the filters it passes to one of two dosing pumps (duty/standby) for each dosing point.

As a measure of safety, Avlon has provided pressure relief valves, so If there is a blockage downstream of the pumps and the pressure within the system reaches that required to open these valves then the chemical will pass either back to the holding tanks (through the overflow lines) or to the bund depending on the type of system. Thereafter, the discharge from both pumps joins a common line so all subsequent items are common to both pumps.

We had also incorporated pulsation damper in our CHU.

The pumps push the chemical forward in pulses and the damper smoothest these so that the chemical is delivered to the dosing point in a constant stream. The damper is at 10 bar pressure. After the pulsation damper is a flow monitor, which detects if the chemical flow rate drops below an adjustable set point. If this happens the duty pump has failed, the standby pump is brought on and an alarm raised. If the standby pump fails to deliver the minimum flow rate then that pump is also failed and a higher priority alarm raised.

After the flow monitor is a pressure gauge that shows the pressure in the dosing system and the back-pressure on the pumps. It can be used to determine the cause of a problem if the system is not working properly, i.e. if the loading valve, which is the next item in the flow path, is blocked and chemical is passing through the pressure relief valves. The loading valve has two purposes. The first is to stop chemical siphoning from the holding tanks to the dosing point. The second is to ensure there is a back-pressure on the pumps so they deliver the dose that they should for a given speed. If the pressure imposed by the loading valve is changed, then the pumps must be recalibrated.

Once the chemical has passed through the loading valve it travels to the dosing point via the dosing line. The calibration pot is used to measure how much the pumps are dosing and if the stroke setting on each pump is right for the required dose rates. The flushing valves are points on the dosing system where lines can be connected and used to flush potable water (not final effluent) through to clean out any chemical before maintenance work is carried out. There is usually one emergency stop button for each pump set. This will fail both pumps.

Automated control of chemical coagulant dosing has not been in widespread use in Philippines up to now with some notable exceptions in recent years. Avlon Inc, having wide experience in water treatment can design customized chemical doing automation system to meet your project requirements. For more information visit us at www.avlon-php.com. Avlon is one of the Best Manufacturers and Suppliers of Sewage Treatment Plant, Wastewater Treatment Plant, Dust Collectors, Wet Scrubbers, Biomass Boilers, Oil/Gas Fired Boiler etc.