WATER TREATMENT PLANT PROCESS

Water treatment plant process may vary slightly at different locations, depending on the technology of the plant and the water it needs to process, but the basic principles are largely the same. The various process followed are briefly explained below. You can visit AVLON INC website for more details too.

Avlon Inc, – A Filipino company

Package Sewage Treatment Plant / Waste Water Treatment Plant manufactures

Guaranteed: DENR RA 9275 Clean Water Act – DAO 2016-08 Standard. Low cost, less footprint, less civil works, less operating expenses, easy to operate modular plug and play system

Visit of website for more details or quotation. www.avlon-php.com

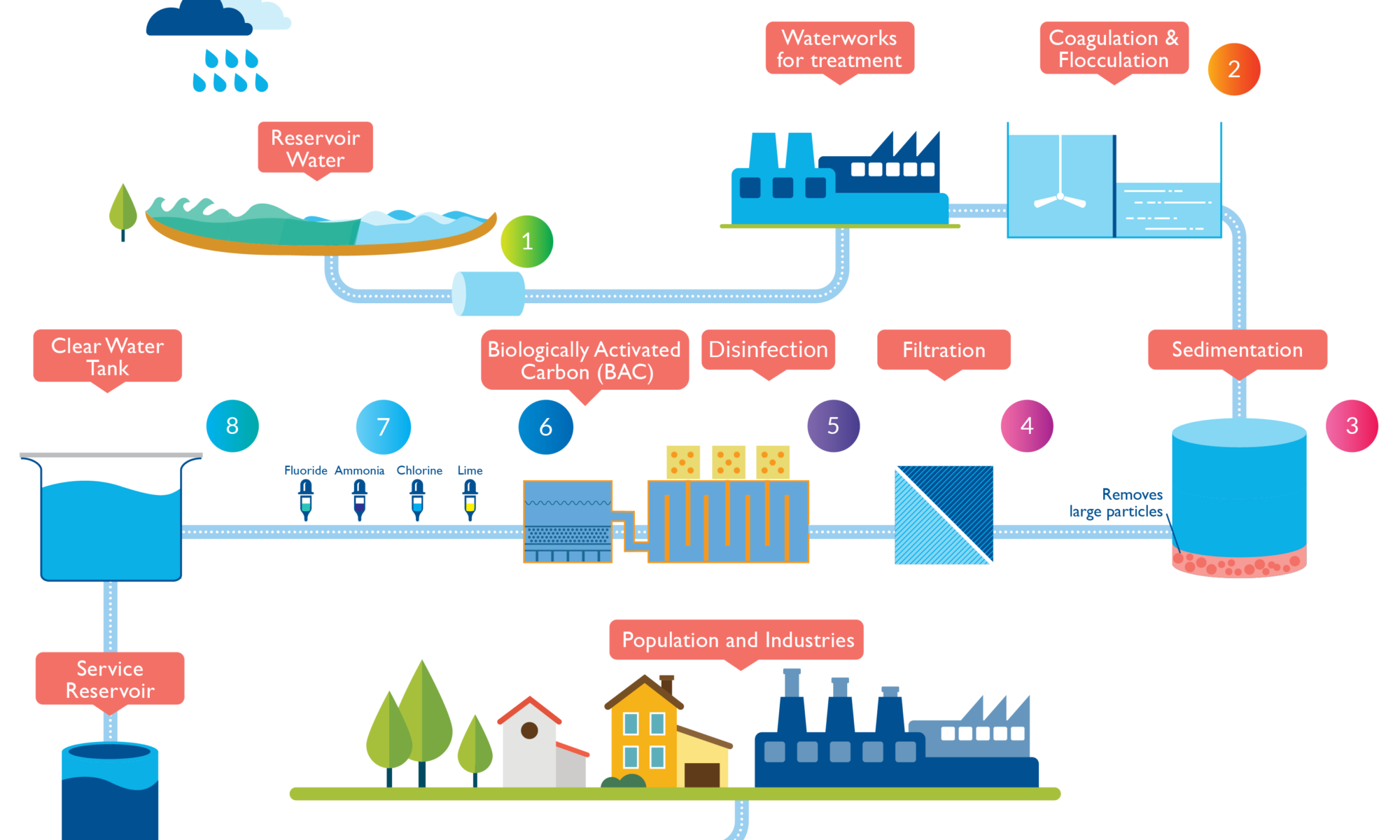

The various process involved in the water treatment as described below:

Stage 1: Screening in water treatment

In Water treatment plant Screening is the first unit operation used at wastewater treatment plants. Screening removes objects such as rags, paper, plastics, and metals to prevent damage and clogging of downstream equipment, piping, and appurtenances. Some modern wastewater treatment plants use both coarse screens and fine screens.

Coarse Screens

Coarse screens remove large solids, rags, and debris from wastewater, and typically have openings of 6 mm (0.25 in) or larger. Types of coarse screens include mechanically and manually cleaned bar screens, including trash racks. Table 1 describes the various types of coarse screens.

Fine Screens

Fine screens are typically used to remove material that may create operation and maintenance problems in downstream processes, particularly in systems that lack primary treatment. Typical opening sizes for fine screens are 1.5 to 6 mm (0.06 to 0.25 in). Very fine screens with openings of 0.2 to 1.5 mm (0.01 to 0.06 in) placed after coarse or fine screens can reduce suspended solids to levels near those achieved by primary clarification.

Stage 2: Pumping

Water treatment plant relies on the force of gravity to move sewage from your home to the treatment plant. So, wastewater-treatment plants are located on low ground, often near a river into which treated water can be released. If the plant is built above the ground level, the wastewater has to be pumped up to the aeration tanks. From here on, gravity takes over to move the wastewater through the treatment process.

Stage 3: Coagulation

During coagulation, liquid aluminum sulfate (alum) and/or polymer is added to untreated water (raw water). When mixed with the water, this causes the tiny particles of dirt present to stick together or coagulate. These groups of dirt particles then join to form larger, heavier particles called flocs, which are easier to remove by settling or filtration.

Stage 4: Aerating

One of the first steps that a Water treatment plant can do is to just shake up the sewage and expose it to air. This causes some of the dissolved gases (such as hydrogen sulfide, which smells like rotten eggs) that taste and smell bad to be released from the water. Wastewater enters a series of long, parallel concrete tanks. Each tank is divided into two sections. In the first section, air is pumped through the water. As organic matter decays, it uses up oxygen. Aeration replenishes the oxygen. Bubbling oxygen through the water also keeps the organic material suspended while it forces ‘grit’ (coffee grounds, sand and other small, dense particles) to settle out. Grit is pumped out of the tanks and taken to landfills.

Stage 5: Sedimentation

As the water and the floc particles progress through the treatment process, they move into sedimentation tanks. Here, the water moves slowly, causing the heavy floc particles to settle to the bottom. The floc that collects at the bottom of the tank is called sludge, and is piped to drying lagoons. In direct filtration, the sedimentation step is not included, and the floc is removed by filtration only.

Stage 6 Removing sludge

Wastewater then enters the second section or sedimentation tanks. Here, the sludge (the organic portion of the sewage) settles out of the wastewater and is pumped out of the tanks. Some of the water is removed in a step called thickening and then the sludge is processed in large tanks called digesters.

Stage 7: Removing scum

As sludge is settling to the bottom of the sedimentation tanks in a Water treatment plant , lighter materials are floating to the surface. This ‘scum’ includes grease, oils, plastics, and soap. Slow-moving rakes skim the scum off the surface of the wastewater. Scum is thickened and pumped to the digesters along with the sludge. Many cities also use filtration in sewage treatment. After the solids are removed, the liquid sewage is filtered through a substance, usually sand, by the action of gravity. This method gets rid of almost all bacteria, reduces turbidity and color, removes odors, reduces the amount of iron, and removes most other solid particles that remained in the water. Water is sometimes filtered through carbon particles, which removes organic particles. This method is used in some homes, too.

Stage 8 Killing bacteria

Finally, the wastewater flows into a ‘chlorine contact’ tank, where the chemical chlorine is added to kill bacteria, which could pose a health risk, just as is done in swimming pools. The chlorine is mostly eliminated as the bacteria are destroyed, but sometimes it must be neutralized by adding other chemicals. This protects fish and other marine organisms, which can be harmed by the smallest amounts of chlorine. The treated water (called effluent) is then discharged to a local river or the ocean

Stage 9: Wastewater Residuals

Another part of treating wastewater is dealing with the solid-waste material. These solids are kept for 20 to 30 days in large, heated and enclosed tanks called ‘digesters.’ Here, bacteria break down (digest) the material, reducing its volume, odors, and getting rid of organisms that can cause disease. The finished product is mainly sent to landfills, but sometimes can be used as fertilizer.